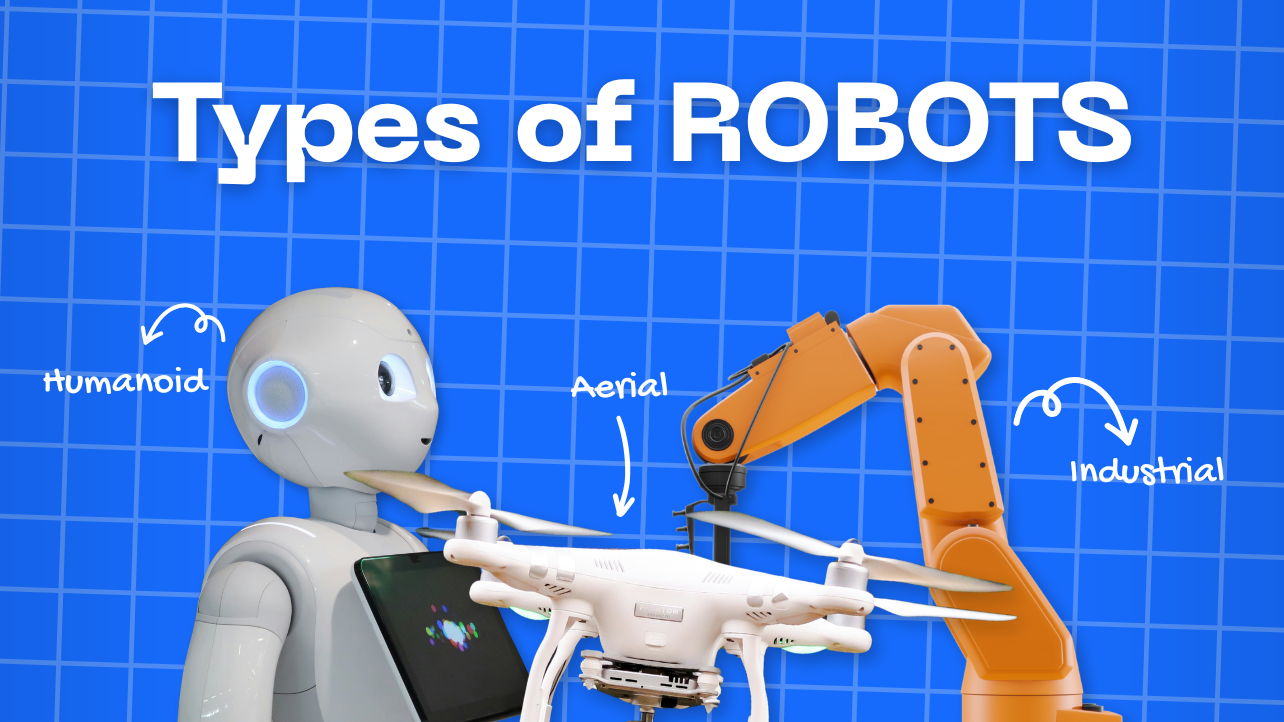

When you hear the word robot, your mind might jump straight to those articulated arms in car factories, or maybe to a humanoid walking around like in sci-fi movies.

But robots are not a single shape or style. They’re designed around a very simple idea: perform a task as efficiently and reliably as possible. And how they achieve that depends on their type.

In this article, we’re not just going to name them. We’ll see how each type actually works, what’s inside them, and the engineering principles that make them move, sense, and act. (also, all photos in this article are from Unsplash. Huge thanks to the talented photographers who share their work freely).

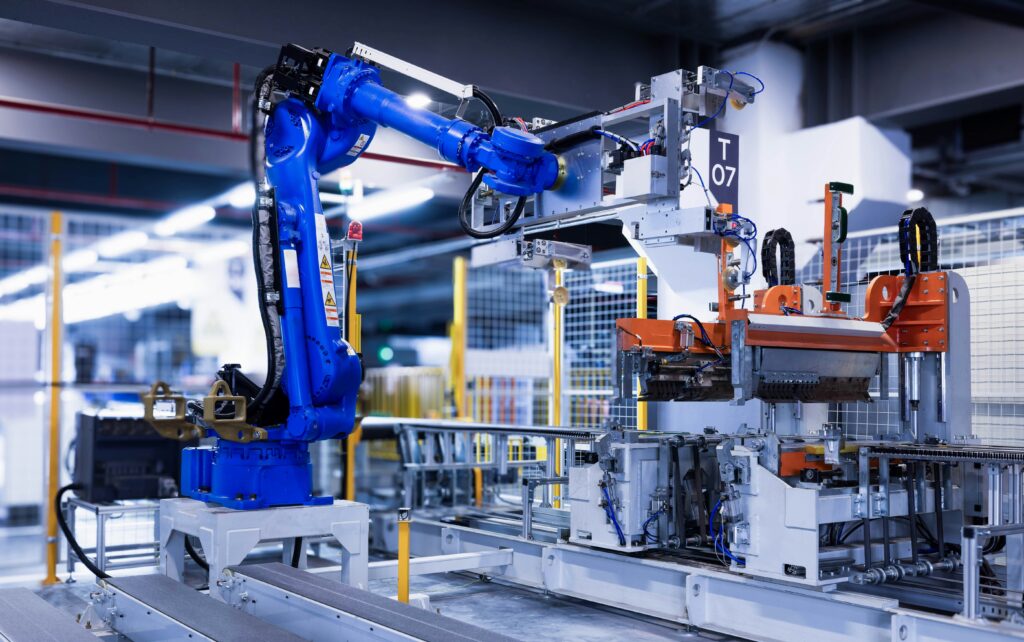

Industrial Robots

Industrial robots are what most people imagine first. They’re built for repetitive and high-precision work: welding, assembling, painting, or picking parts from one place to another.

The articulated arm being among the most common ones, as it is shown in the photo above is a mechanical interpretation of a human arm (shoulder, elbow, wrist) but each joint is a motor. The brain behind it runs equations (mostly forward/inverse kinematics) to figure out exactly how each joint should move so the “hand” or tool ends up in the right spot.

And they are composed of:

- Actuators: Usually servo motors with encoders, so the robot always knows its joint positions.

- Controller: It calculates joint positions from the target coordinates.

- End effector: The “tool”, could be a gripper or a welder.

They’re fast, strong, and precise, but they need a fixed workspace with safety barriers. Without them, one wrong move and you’ve got a flying metal arm (not in the cool way).

Articulated arms are just one configuration. Industrial robotics also includes SCARA, Gantry/Cartesian, Delta, and other designs, each with its own strengths.

Collaborative Robots (Cobots)

Collaborative robots, or cobots in short, are designed to work alongside humans instead of being isolated behind safety fences. You’ll often see them in factories with an operator there.

Like industrial robots, they have joints, actuators, and a controller, but cobots include extra safety features: force and torque sensors, soft edges, and speed limits, some of them even depend on computer vision and AI. If they detect unexpected contact, they stop immediately. Many can be programmed simply by guiding their arm through the motion, a method called “lead-through” teaching.

Cobots vs. Industrial Robots

Industrial robots are built to replace human labor in high-speed, high-load, and often hazardous tasks. They operate in fenced-off areas, repeating fixed programs at maximum speed. Their controller focuses on executing precise motion paths as efficiently as possible.

Cobots, in contrast, are built to share the workspace. Their control systems constantly process safety inputs from sensors, vision systems, and force feedback while executing movements. This makes them adaptive but limits their speed and payload.

In short:

- Industrial robots = Fast, powerful, isolated, programmed for fixed cycles.

- Cobots = Safe, adaptive, and human-friendly.

Mobile Robots

Not every robot is bolted to the ground. Mobile robots move to where the job is, from warehouse AGVs to delivery bots, or even those robots we (as students) build for competitions, like a car accompanied with a line following algorithm, or a quadruped robot, but let’s go back to the serious ones.

We often find inside the system:

- Locomotion: Wheels (simplest), tracks for rough terrain, or even legs.

- Navigation: LIDAR, cameras, and odometry sensors help them “see” and track movement.

- Path planning: Algorithms find the safest and shortest route, A* for example.

The hard part here is SLAM (Simultaneous Localization and Mapping). In other words, building a map while figuring out where you are on it.

Humanoid Robots

Humanoids try to replicate the human body, which is much harder than it sounds. In addition, they are very known in the robotics community, try typing in Google “robot” and I’m certain you’ll see a humanoid robot in the images. I didn’t even have a problem searching a photo for it.

Walking on two legs is a balancing act, literally. The robot constantly shifts its weight to keep from falling. Those robots can be considered mobile too.

For sensing, we use gyroscopes and accelerometers to get the robot’s state in order to achieve balance balance, then its controller treats the data, comes up with correct values then send them to high-torque motors or hydraulics for each joint.

The controller here also depend on some algorithms to plan every step so the center of mass stays above the feet.

And it’s not just walking, even standing still takes constant adjustments. That’s why making a humanoid that moves naturally is still one of robotics’ biggest challenges.

Aerial Robots

Drones are flying robots that use feedback loops to stay stable, like a PID controller or a Kalman Filter controller.

This is how they keep being steady:

- Rotors (for quadcopters) or wings (for fixed-wing drones) are here to lift the robot.

- To control the attitude, an onboard IMU measures pitch, roll, and yaw.

- The control system here adjusts motor speeds in milliseconds to counter tilt.

It’s a constant fight against gravity and wind, the controllers never stop making small corrections.

Aquatic Robots

Once you take robotics underwater, the rules change. Water drags on every movement, pressure pushes harder the deeper you go, and radio signals, the same ones we use for Wi-Fi or remote control, barely make it past a few centimeters.

Most underwater robots move using thrusters, which are basically small propellers that can push the robot forward, backward, or sideways. To control depth, they use ballast systems or adjustable tanks to take in or expel water, making them sink or float.

Since light fades quickly underwater, vision isn’t always reliable. That’s why these robots rely heavily on sonar, sending sound waves out and timing the echo to “see” the surroundings, even in pitch black.

Some are autonomous, carrying batteries and onboard computers. Others stay connected to the surface with a tether, which provides both power and a high-speed data link. The tether might look like a simple cable, but it’s the robot’s lifeline, without it, you’re relying on limited onboard energy and slow acoustic communication.

Service and Special-Purpose Robots

Some robots are designed for one job and one job only, like a surgical robot or a firefighting bot.

Everything about them, shape, sensors, control system, and so much more, is built around that specific task.

That’s why a da Vinci surgical robot moves like a steady hand, while a firefighting robot carries high-pressure hoses and heat-resistant armor.

Once you know how each type works, you start noticing the same engineering building blocks everywhere: actuators, sensors, controllers, and clever algorithms tying it all together, and this is something we discussed on in our robotics’ article.

The difference lies in how those blocks are combined for a particular job.

If you understand the principles, you can go from observing a warehouse arm to sketching your own robot project.

No comments yet